Making your production more predictable

In order for the finished product to leave the company on schedule, production and internal material flow must be synchronized. Raw and packaging materials are required to arrive at their destination on time, and finished parts need to be booked to inventory immediately. The COGLAS logistics solution controls all those transport, handling and storage processes ensuring your whole production process including work schedules and production orders to be calculated and predictable.

Easily integrated

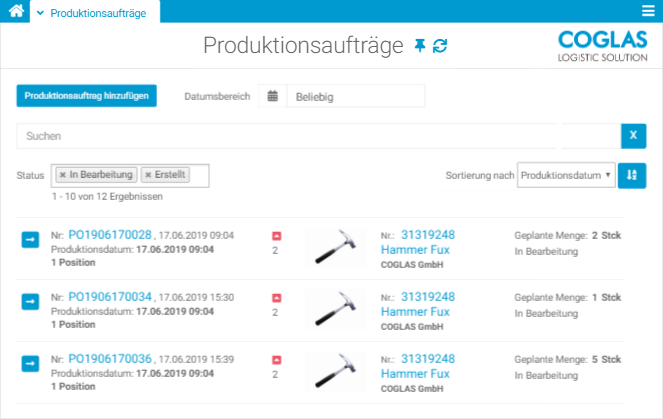

Connect this system to your production planning and control system. The system transfers scheduled orders and translates them into production orders.

Up-to-date information at all times

After production, each individual component is directly updated in the inventory giving you constant up-to-date inventory data so you can initiate shipping immediately.

Compatible with Kanban

The COGLAS solution can also be used to control the delivery of Kanban parts. This can be initiated either by barcodes or RFID.

Versatile and easy-to-use production control

At the heart of the COGLAS solution is the production order. It is here that goods scheduled for production are listed with their article numbers and respective quantities. Inside you can find the production date, the desired production route, and your follow-up strategy for the end-of-line removal of the finished product. Details such as material numbers, batch allocation and required loading equipment are stored at the individual item level.

Upon completion of production, a production receipt is recorded. Here you can also specify quantity variances with respect to the planned order. This means that it is possible to enter higher or lower quantities. Completed units are then distributed to the amount of target storage units as calculated by the system.

At each stage, a convenient interface displays the current production status and inventory volumes in real time.

Suitable for all forms of production

The COGLAS logistics solution can be used in all industries and production scenarios and adapted to your processes due to its simple and time efficient design.

With Route Management

COGLAS can be used to control and monitor assembly lines supplied with tugger trains. Thus, reducing the traffic volume and increasing efficiency.

Customised production

With COGLAS you can plan and account for individual product customisations and refinements for your customers using individual parts lists and working schedules.

Flexibly adaptable